Top Supplier in China Exported to 90+ Countries Solid Composite Decks

Solid Composite Decks vs Hollow Composite Decks

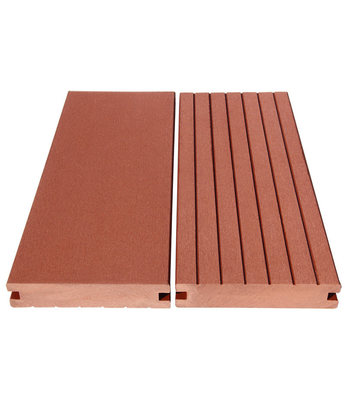

The COOWIN composite decking series includes both solid and hollow trim boards. So, what are their differences?

Solid panels have greater durability. While both solid composite decking and hollow composite decking are strong enough to withstand a considerable amount of weight. But the more densely structured solid composite decking is obviously stronger. If you need to put heavy loads on the deck, obviously solid composite decking is the best choice.

Secondly, solid composite decking is more like real wood. After all, traditional wood decks do not have the type of hollow decking. If you want a solid wood-like appearance, solid composite trim boards are better for you.

The disadvantage of solid trim boards is that they are susceptible to extremes of temperature and humidity. Excessive temperature changes can cause solid composite decking to expand or contract. Therefore, you are better off choosing hollow core composite decking if you live in a beach town or a city that experiences high seasonal temperature changes.

Solid Composite Decks Specification

|

Surface

|

3D wood grain or groove surface

|

|

Color

|

cedar, red pine, redwood, light gray, coffee, blue-gray

cedar art, red pine art, redwood art, light gray art, red-brown art

|

|

Length

|

2.2m, 2.7m, 5.4m or customized

|

|

WPC formula

|

50% wood fibers + 38% HDPE + 12% additives

|

|

Certificates

|

CE, ISO9001, FSC, SGS test report including all test items, etc

|

|

Advantages

|

100% recycled, innocuous, waterproof, anti-UV, better resistance to fire, easy to install, no crack, no split, no warp, no splinter, antisepsis, no painting, no maintenance, etc

|

|

Packaging

|

PE film, carton board, plywood, waterproof clothing, pallet, bandage, etc. NO WOOD

|

|

Applications

|

Garden, hotel, park, yard, balcony, beach road, swimming pool surrounding, etc

|

|

Lifetime

|

25-30 years

|

Important Tip of Solid Composite Decks

COOWIN can assist you before you begin your outdoor deck project. You can simply accomplish a high-quality outdoor project with our helpful hints and installation instructions.

Please factor in an additional 5% of material when designing your project to avoid running out.

Make sure your deck's joists are no more than 30 cm apart, allowing for double joists in cases where butt joints are required.

Install the first composite deck with precision using the starting fasteners. After that, matching hidden fasteners are recommended for a quick and secure installation.

Allow enough space between neighboring composite deck joints to allow for deck expansion.

Use a straight board to guide the circular saw when trimming to the size of the deck edge. This will give the composite trim board a more defined edge.

Solid Composite Decks FAQ

Q1: What is Wood Plastic Composite?

A: Wood Plastic Composite (WPC) is a type of eco-friendly material made of reclaimed wood fiber and polymers. COOWIN WPC Decking and Cladding, manufactured with our patented formula and by an innovative dual-screw extrusion process, combine superior performance with naturalistic looks and textures of real wood. COOWIN is the first that has adopted Color Streaking and 3D Wood Grain Technology for uncapped WPC products in the industry. Compared with LDPE, HDPE-based composites are stronger and stiffer.

Q2: What does the term "Art Color" mean?

A: Art Color is a term used to describe the varied streaking on COOWIN composite decking and cladding. By adding different colors at precise moments during the manufacturing process, we are able to create a more nuanced color palette, or maybe variegated color, on a monotonous board, to create the rich, natural color variation found in real wood such as cedar, redwood, and ipe.

Q3: Is your product less harmful to human health than a comparable conventional product?

A: Yes. COOWIN composite contains no added arsenic or other preservatives that are likely to be toxic under normal exposure conditions. Conventional wood treating processes impregnate the wood substrate with toxic chemicals to prevent rot and decay.COOWIN composite is naturally resistant to rot and decay without toxic additives.

Q4: Is your WPC material waterproof?

A: COOWIN WPC has excellent moisture resistance, however, it should be noted that COOWIN WPC is not designed to “live in moisture”, this will eventually cause swelling and affect physical properties.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!